1. Fiber laser cutting machine

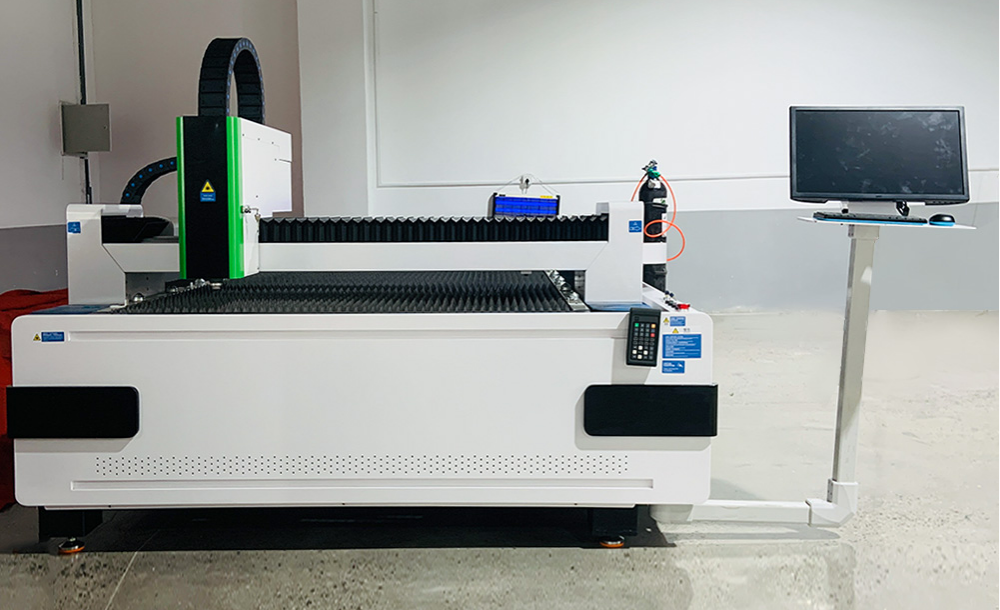

Fiber laser cutting machine is a laser processing equipment that uses a fiber laser generator as the light source.

Fiber laser is a new type of fiber laser developed internationally. It outputs a high-energy density laser beam, gathers on the surface of the workpiece, and moves the spot irradiation position through a CNC machine tool system, causing the workpiece to instantly melt and evaporate in the ultra-fine focal length spot irradiation area, and achieving automatic cutting in this system. Compared with a large number of gas lasers, solid-state lasers have obvious advantages and have gradually developed into important candidates in fields such as high-precision laser processing, LiDAR systems, space technology, and laser medicine.

2. CO2 laser cutting machine

CO2 laser cutting machine can stably cut carbon steel up to 20mm, stainless steel up to 10mm, and aluminum alloy up to 8mm. The wavelength of CO2 laser is 10.6UM, which makes it more easily attracted by non-metals and can cut non-metallic materials such as wood, acrylic, PP, and organic glass with high quality. However, the photoelectric conversion rate of CO2 laser is only about 10%.

The CO2 laser cutting machine is equipped with a nozzle, which blows oxygen, compressed air, or inert gas n2 at the beam outlet to improve cutting speed and smoothness. Used for the discharge stability of high-power lasers corresponding to CO2 gas lasers, increasing the stability and service life of the power supply. According to international safety standards, the danger level of lasers is divided into four levels, and CO2 lasers belong to a very low danger level. However, the cost of using CO2 laser cutting machines is very high among these three types of laser cutting machines.

3. YAG laser cutting machine

YAG solid laser cutting machines have low cost and good stability, but their energy efficiency is generally low.

The laser wavelength of YAG solid laser cutting machine is difficult to be absorbed by non-metals, so it cannot cut non-metallic materials; The challenge of YAG solid laser cutting machine lies in improving the stability and service life of the power supply, that is, developing a high-capacity and long-life optical pump to excite the light source.