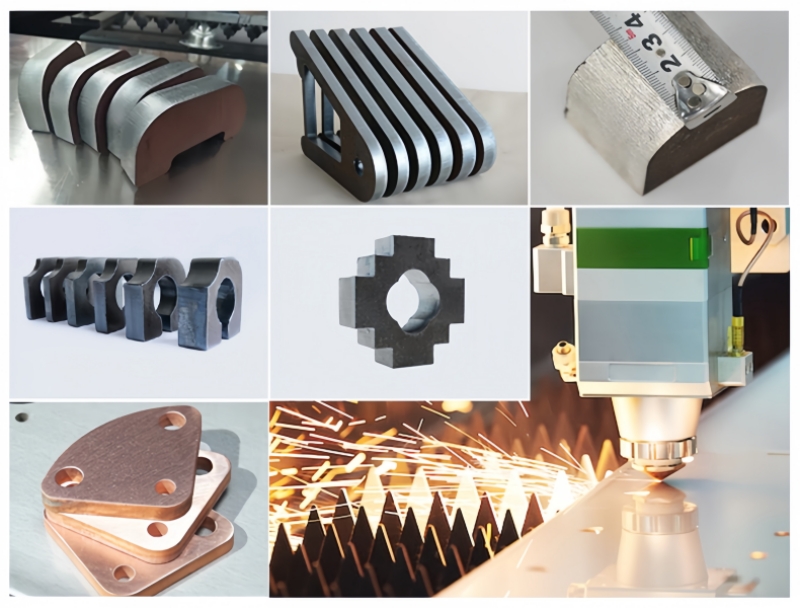

1. Metal materials

Metal materials are the most common processing objects in laser cutting. When laser cutting metal, the metal surface will quickly melt and form cutting seams, and the generated heat will cause heat affected zones to form at the edges of the material. To reduce the heat affected zone, auxiliary gases such as nitrogen or oxygen are usually used during the cutting process.

In terms of creation, the characteristics of metal materials can be utilized for the production of laser cut artworks. For example, various patterns and texts can be designed on metal plates, and they can be precisely cut out through laser cutting technology to create metal artworks with a sense of three dimensionality and hierarchy.

2. Non metallic materials

In addition to metal materials, laser cutting can also be applied to some non-metallic materials, such as wood, plastic, and glass. These materials also undergo different reactions during laser cutting.

During the laser cutting process of wood, the edges of the cutting seam will show a burning phenomenon, which is due to the decomposition of cellulose in the wood at high temperatures. To achieve better cutting results, auxiliary gases or pre-treatment can be used during the cutting process.

During laser cutting, plastic usually undergoes melting, forming a thin layer of molten material. This molten layer can be used to create art pieces with special effects, such as reliefs or three-dimensional patterns.

During the laser cutting process of glass, the laser beam will quickly melt the surface of the glass and form cutting seams. Due to the high transparency of glass, unique patterns and textures can be formed inside the glass using laser beams during the cutting process, creating glass artworks with unique aesthetics.

3. Composite materials

Composite materials are new materials composed of two or more materials with different properties. During laser cutting, different components in the composite material will produce different reactions, presenting a rich visual effect.

For example, laser cutting can be performed on composite materials of metal and plastic, utilizing the different reactions of metal and plastic under laser action to create artworks with both metallic and plastic textures. In addition, laser cutting can also be performed on composite materials of wood and glass, achieving perfect fusion between wood and glass by adjusting laser parameters and using auxiliary gases.