1. Replacement of water and cleaning of water tank

It is generally recommended to clean the water tank and replace the circulating water once a week, and make sure that the laser tube is filled with circulating water before the machine starts working. Because the water quality and temperature of the circulating water directly affect the service life of the laser tube, it is recommended to use pure water and control the water temperature below 35 ℃. If the temperature exceeds 35 ℃, it is necessary to replace the circulating water or add ice to the water to reduce the water temperature (it is recommended that users choose a cooling machine or use two water tanks).

2. Equipment fan cleaning

Long term use of a fan can accumulate a lot of solid dust inside, causing significant noise and hindering exhaust and odor removal. When the suction of the fan is insufficient and the smoke exhaust is not smooth, first turn off the power, remove the inlet and outlet pipes on the fan, remove the dust inside, then invert the fan and pull the fan blades inside until they are clean, and then install the fan.

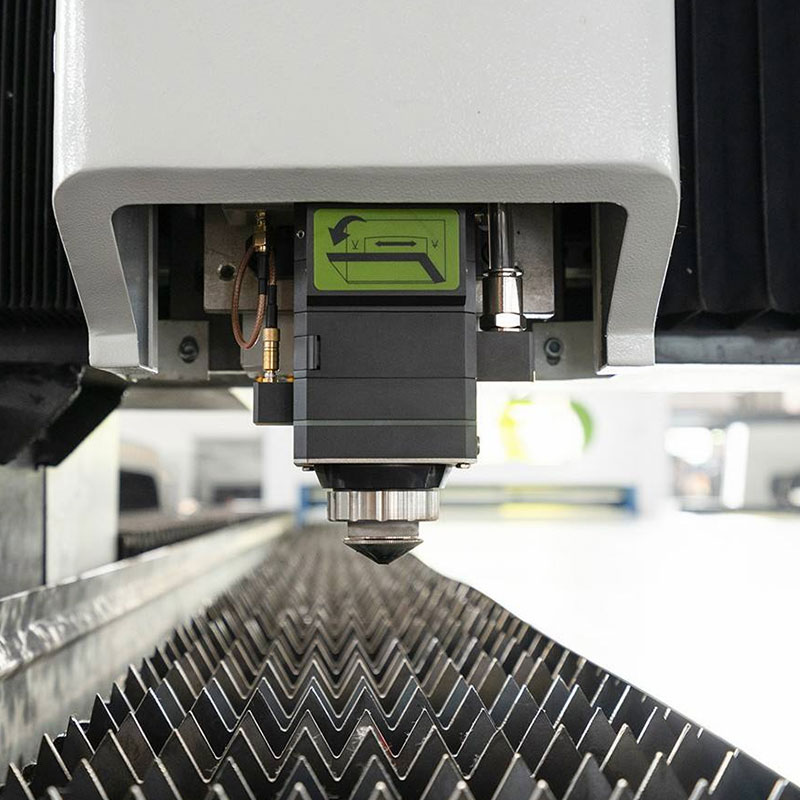

3. Cleaning of lenses

It is recommended to clean before work every day, but the laser cutting machine must be turned off. There are three reflective mirrors and one focusing mirror on the machine, and the laser is reflected and focused through these lenses before being emitted from the laser hair. Lenses are easily contaminated with dust or other pollutants, causing laser loss or lens damage. When cleaning lenses 1 and 2, do not remove them. Just carefully rotate the wiping paper dipped in cleaning solution along the center and edge of the lens. The No.3 lens and focusing lens need to be removed from the frame and wiped using the same method. After wiping, they can be reinstalled in their original state.

4. Cleaning of machine guide rails

Suggest cleaning every two weeks and shutting down the machine. As one of the core components of equipment, guide rails and linear shafts serve as guiding and supporting functions. In order to ensure high machining accuracy of the machine, it is required that its guide rails and straight lines have high guiding accuracy and good motion stability. During the operation of laser equipment, a large amount of corrosive dust and smoke are generated during the processing of the workpiece. These smoke and dust deposit on the surface of the guide rail and linear axis for a long time, which has a significant impact on the processing accuracy of the equipment. They also form corrosion points on the surface of the guide rail linear axis, shortening the service life of the equipment.