1、 Clarify cutting requirements

Before choosing a laser cutting machine, enterprises need to conduct in-depth analysis of their production needs. Different materials, thicknesses, and cutting shapes have varying requirements for the power, accuracy, and stability of the equipment. For example, the cutting of metal sheets requires high-power lasers, while non-metallic materials such as plastics and fabrics do not require high laser power. Therefore, clarifying the cutting requirements helps to determine the performance parameters of the required equipment.

2、 Pay attention to device performance and parameters

1) Laser type: Laser is the core component of laser cutting machine, and its performance directly affects the cutting effect. Common types of lasers include pulse lasers, continuous wave lasers, and fiber lasers, each with different applicable ranges and advantages and disadvantages. Enterprises need to choose the appropriate type of laser according to their actual needs.

2) Cutting accuracy and speed: Accuracy and speed are important indicators for evaluating the performance of laser cutting machines. High precision and high-speed equipment can help improve production efficiency and reduce defect rates. When purchasing, pay attention to the repeated positioning accuracy and maximum cutting speed of the equipment to ensure that it meets production standards.

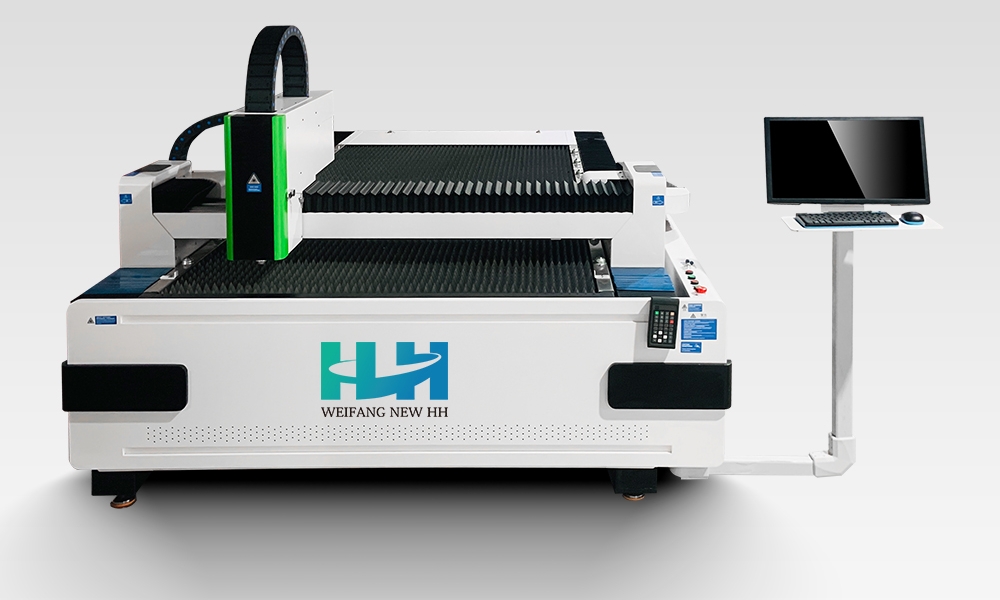

3) Table size and motion system: Select a cutting machine with the appropriate table size based on the production scale and the size of the workpiece being processed. At the same time, pay attention to the stability and accuracy of the motion system to ensure that the equipment can perform efficient and accurate processing.

3、 Equipment stability and after-sales service

1) Equipment stability: As a high-value equipment, the stable operation of laser cutting machines is crucial for reducing maintenance costs and ensuring production continuity. When purchasing, it is important to fully understand key data such as equipment failure rate and mean time between failures, and choose brands and models with high stability.

2) After sales service: A comprehensive after-sales service system can solve equipment usage problems for enterprises, shorten downtime, and improve production efficiency. When choosing a laser cutting machine, it is important to pay attention to the manufacturer's after-sales service capabilities and service quality.

4、 Comprehensive cost assessment

In addition to equipment procurement costs, enterprises should also consider operating costs, maintenance costs, and training costs. Comprehensively evaluate the total cost of different solutions and select the laser cutting machine with the best cost-effectiveness.