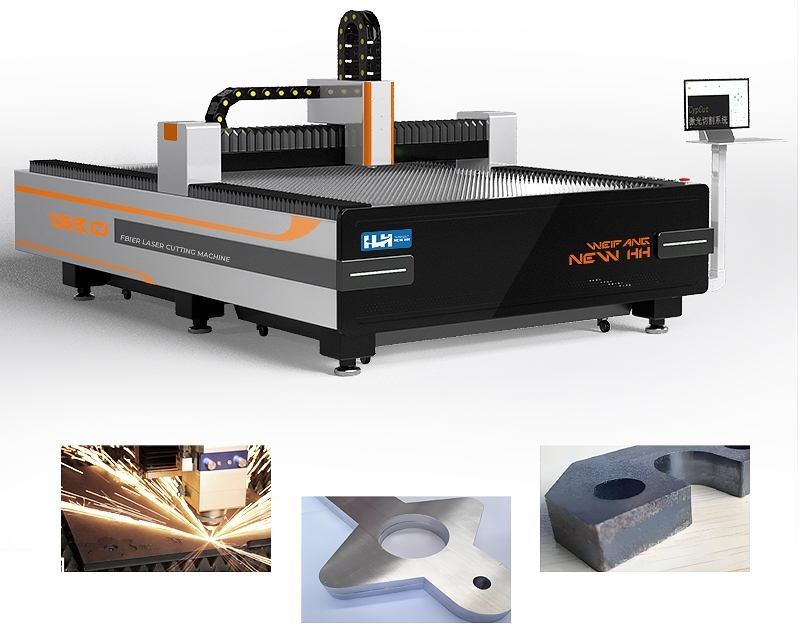

In the field of sheet metal processing, with the increasing application and proportion, CO2 laser applications have faced strong challenges. Fiber laser has low energy consumption, accounting for only one-third of CO2 laser; Secondly, due to the wavelength, metal materials have a much higher absorption rate for fiber lasers than CO2 lasers, resulting in extremely high processing efficiency. In the field of thin metal plate cutting, fiber laser equipment has surpassed CO2 laser equipment and has quickly and extensively occupied the space of ordinary punching function presses. In laser cutting applications, it is inevitable to encounter various problems of one kind or another.

What are the current problems in the sheet metal industry processing?

The traditional processing method in the sheet metal workshop is to use the process flow of cutting, punching, and bending. The punching process requires a large number of molds, and punching in the sheet metal workshop has the characteristics of low cutting and no cutting, which is very important. In this way, it is generally necessary to equip dozens of sets of molds during the processing of a product, and some products may require hundreds of sets of molds.

What factors affect the absorption of laser energy by processing materials?

When laser passes through processed materials, the material absorbs the laser. Due to the different internal structures and compositions of the material, the absorption of laser is also different. The wavelength, conductivity, surface roughness, coating, and temperature of the material all affect the material's absorption of laser energy.

What are the effects of abnormal sparks when cutting low carbon steel? How to deal with this phenomenon?

This situation will affect the cutting surface smoothness and machining quality of the parts. In the absence of a new nozzle replacement, the cutting gas pressure should be increased.

What are the influencing factors of incomplete laser cutting?

The selection of laser nozzle does not match the thickness of the processing plate; The laser cutting line speed is too fast and needs to be controlled to reduce the line speed.

When laser cutting stainless steel and aluminum zinc coated plates, which situation does the workpiece have burrs?

Firstly, consider the factor of burrs when cutting low carbon steel, but it is not enough to simply increase the cutting speed, as increasing the speed may sometimes result in the plate not being cut through, which is particularly prominent when processing aluminum zinc coated plates. At this point, other factors of the machine tool should be considered comprehensively to solve the problem, such as whether the nozzle needs to be replaced, unstable guide rail movement, etc.

What are the effects of abnormal sparks when cutting low carbon steel? How to deal with this phenomenon?

This situation will affect the cutting surface smoothness and machining quality of the parts. In the absence of a new nozzle replacement, the cutting gas pressure should be increased.

What are the influencing factors of incomplete laser cutting?

The selection of laser nozzle does not match the thickness of the processing plate; The laser cutting line speed is too fast and needs to be controlled to reduce the line speed.

When laser cutting stainless steel and aluminum zinc coated plates, which situation does the workpiece have burrs?

Firstly, consider the factor of burrs when cutting low carbon steel, but it is not enough to simply increase the cutting speed, as increasing the speed may sometimes result in the plate not being cut through, which is particularly prominent when processing aluminum zinc coated plates. At this point, other factors of the machine tool should be considered comprehensively to solve the problem, such as whether the nozzle needs to be replaced, unstable guide rail movement, etc.

What are the reasons for deformation of small holes (diameter and plate thickness) during cutting and processing?

Machine tools (only for high-power laser cutting machines) do not use explosive perforation when processing small holes, but use pulse perforation (soft puncture), which makes the laser energy too concentrated in a very small area, burning the non processing area and causing deformation of the hole, affecting the processing quality.

What are the solutions to burrs when laser cutting low carbon steel?

The up and down position of the laser focus is incorrect, and a focus position test is needed to adjust it based on the offset of the focus; The output power of the laser is insufficient. It is necessary to check whether the laser generator is working properly. If it is normal, observe whether the output value of the laser control button is correct and adjust it accordingly; The cutting line speed is too slow and needs to be increased during operation control; The purity of the cutting gas is insufficient, and high-quality cutting working gas needs to be provided; Laser focus offset requires focus position testing and adjustment based on the offset of the focus; The instability caused by prolonged operation of the machine tool requires a shutdown and restart.