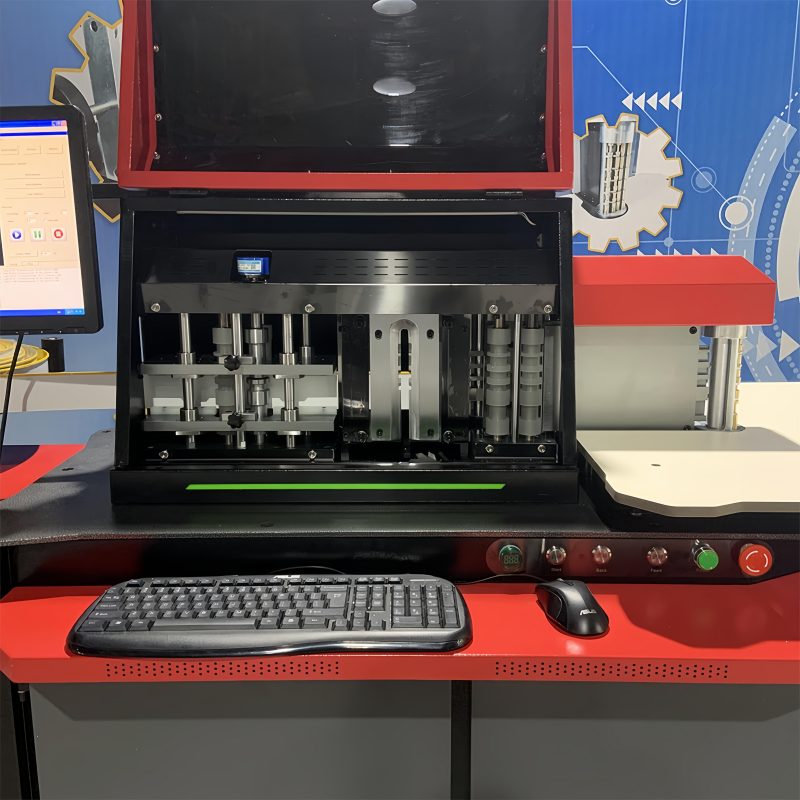

In the field of advertising font production, a bending machine is a common advertising font edge device that can be used to create exquisite luminous advertising characters. Bending machines, also known as wrapping machines, are the same device with the same function, but with different names. The fully automatic bending machine is an automated advertising equipment controlled by software and processed by programs, used to automatically bend and shape the outer contour of metal luminous characters.

In the current advertising production industry, the literal processing of metal luminous characters is mainly completed through carving machines or plasma cutting machines. With the rapid development of the advertising production industry, advertising equipment for literal processing has entered a mature development period; The emergence of the bending machine is bound to bring a revolutionary breakthrough to the advertising production industry. Through software control, the bending machine can accurately fold out the edges of metal characters and achieve high-precision embedding with the face and bottom plate, greatly increasing the intensity and aesthetics of luminous characters.

Precautions for using the bending machine:

1. It is best to place the fully automatic bending machine in a dry environment to avoid oil stains and high pressure.

2. The rated voltage of the bending machine is 220V. When using it, connect it to the ground to prevent static electricity.

3. The bending machine needs to be connected to an air compressor and adjusted to an appropriate pressure, usually 0.4MPa-0.8MPa. After installation, check whether the air compressor and air pipe are leaking.

4. It is best to remove excess nodes when repairing characters, as too many nodes will affect accuracy and curvature. After repairing, import the fully automatic bending machine software.

Daily maintenance of the bending machine:

(1) Do a good job in dust removal for various parts of the bending machine. Once dust enters the interior of the equipment, it can cause significant inconvenience, affect the normal use of the equipment, and affect production efficiency. So in daily use, it is necessary to clean the machine table and the surface of the casing, and do a good job of cleaning.

(2) Do a good job in rust prevention for the bending machine. Once the equipment rusts, it can cause some components to age and reduce work efficiency. Therefore, it is necessary to regularly apply rust proof oil to the bending machine equipment to avoid rusting.

(3) Do a good job in lubricating the transmission device of the bending machine. When the equipment is running, if the transmission device of the equipment is not running smoothly, it will lead to uneven feeding of the equipment, affecting the quality of the material and causing a certain impact on industrial production. So in daily maintenance, it is also necessary to lubricate the feeding transmission device of the bending machine.