In today's industrial manufacturing field, CO2 laser cutting machines have become an important tool for paper processing. This high-tech equipment has brought revolutionary changes to the paper processing industry due to its efficient, precise, and environmentally friendly characteristics. This article will provide a detailed introduction to the principle, application scenarios, and operating techniques of CO2 laser cutting machines, helping readers better understand the cutting-edge technologies in this field.

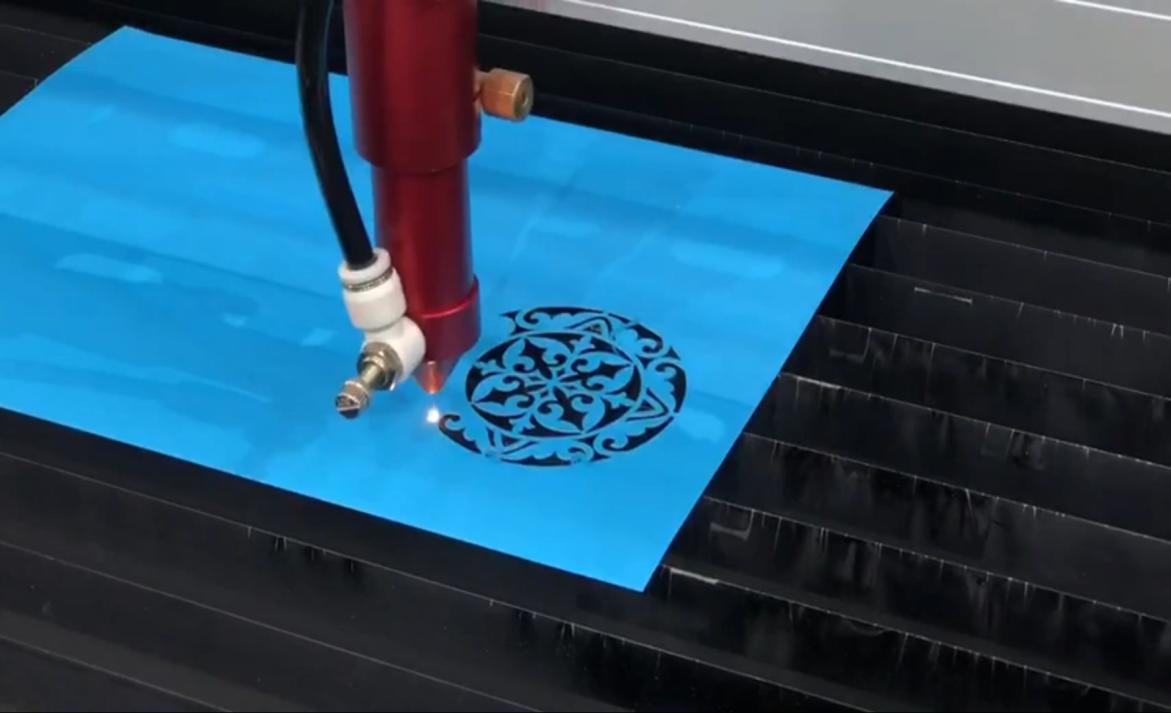

Firstly, let's understand the principle of CO2 laser cutting machine. The CO2 laser cutting machine uses a high-energy CO2 laser beam to irradiate the surface of paper, converting light energy into heat energy, causing the paper to instantly melt, vaporize, or burn, thereby forming the desired pattern or text. This processing method has extremely high accuracy and speed, and can meet the processing needs of various complex shapes and sizes of paper products.

In terms of application scenarios, CO2 laser cutting machines are widely used in industries such as advertising, packaging, decoration, printing, and textiles. For example, in the advertising industry, CO2 laser cutting machines can quickly cut various shapes and sizes of billboards, display racks, flyers, etc; In the packaging industry, CO2 laser cutting machines can accurately cut various shapes and sizes of packaging boxes, labels, hanging tags, etc; In the textile industry, CO2 laser cutting machines can cut various patterns and patterns, which are used to make clothing, ties, scarves, etc.

In terms of operating skills, the operation of CO2 laser cutting machine is relatively simple. Firstly, design CAD files based on the patterns or text to be cut as needed; Secondly, import the designed CAD file into the laser cutting machine control system; Finally, start the laser cutting machine for cutting. It should be noted that during the operation, the paper should be kept flat and clean to avoid affecting cutting accuracy.

In summary, CO2 laser cutting machines have brought revolutionary changes to the paper processing industry due to their high efficiency, precision, and environmental friendliness. CO2 laser cutting machines play an important role in industries such as advertising, packaging, decoration, printing, and textiles. At the same time, we also need to pay attention to operational skills and safety issues to ensure that accidents do not occur during use. I believe that with the continuous development of technology, CO2 laser cutting machines will play a more important role in the future, bringing more innovation and breakthroughs to the paper processing industry.